Products

Product Search

Quickly find the products you need.

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Disposable hotsell PE film baby diaper back sheet raw materials making for diaper

- ITEM NO: Disposable hotsell PE film baby diaper back sheet raw materials making for diaper

Email: Info@glinkscm.com

Category:

Detailed Introduction

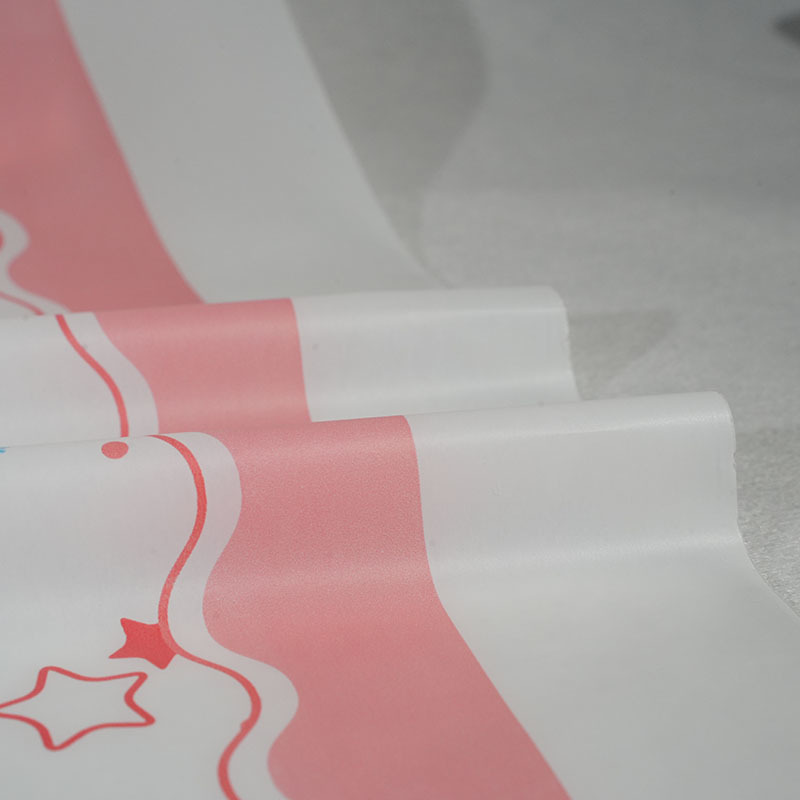

The disposable PE film raw material in diapers is made through a casting process.

The casting process is a plastic film production process, with the following specific steps:

Plasticization and melting of raw materials: Firstly, the raw materials are plasticized and melted through an extruder.

Molding die extrusion: Molten raw materials are extruded through a T-shaped structure molding die to form a sheet-like film.

Casting cooling: The film is cast onto the surface of a smoothly rotating cooling roller, and then cooled and shaped.

Traction and trimming: After shaping on the cooling roller, the product is finally wound up through traction and trimming.

The application of cast film in diapers is mainly reflected in its softness, breathability, and water absorption performance, which can provide better comfort and user experience.

PE film raw material features:

Material | Polyethylene |

Processing Type | Casting |

Width | 70-2200 mm, customized |

Basic weight | 12-100 gsm, customized |

Color | Customized, 1-8 colors |

Feature | Moisture proof |

Roll diameter | As required |

Loading quantity | 15tons/20GP, 25 tons/40HQ |

Function | Baby diaper backsheet |

Product name | Disposable PE film raw material | |||

Specification | 20gsm*320mm | |||

Item | Unit | Standard | Result | |

Basic Weight | gsm | ±2.0 | 20.2 | |

Width | mm | ±2.0 | 320 | |

Tensile Strength | MD Tensile | N | ≥5.0 | 7.47 |

CD Tensile | N | ≥2.0 | 6.18 | |

Break Elongation rate | MD Elongation | % | ≥100 | 604 |

CD Elongation | % | ≥200 | 596 | |

Corona | dyne | ≥38 | 38 | |

Get Quote